[Professional] ISO 2135 Artificial light accelerated test

Recently, a new test method for the lightfastness of anodes has been added to the industry. Its full title is "Aluminum and Aluminum Alloy Anodizing - Artificial Light Accelerated Test of Colored Anodic Oxide Films." We have briefly excerpted its relevant content for your reference. The relevant content is as follows:

About ISO 2135

- Scope

This test method is an accelerated lightfastness test method developed for anodic oxide coatings on aluminum and its alloys, using artificial light sources to evaluate the color resistance to fading.

- Principle

Using simulated UV light, such as a xenon or carbon arc lamp, and controlling light and temperature conditions, the color fading of the workpiece is observed at an accelerated rate. Weathering resistance and light stability are then evaluated against a grayscale standard.

- Limitations

This method is only applicable to anodic oxide coatings whose lightfastness has been confirmed by outdoor exposure testing and whose lightfastness is at least Class 6. It is not applicable to products with a lightfastness lower than this value.

- Update

This is a new standard that supersedes ISO 2135:2017 and continues to be under the jurisdiction of Technical Committee ISO/TC 79/SC 2.

Test points

- Purpose and Scope

This test simulates the effects of outdoor sunlight on colored anodized aluminum coatings. This test is suitable for color coatings that have been confirmed to have a lightfastness rating of 6 or higher through outdoor exposure testing. This test serves as a quality control measure for the manufacturing process.

- Test Conditions

A D65 filtered xenon arc lamp is used to simulate the full sky spectrum (UV + Visible + Infrared). The Black Panel Temperature (BPT) is typically set to 63 ± 3°C, though 50 ± 3°C is acceptable. The actual test value must be agreed upon by both parties.

Evaluation Process

- Clean the sample and determine the test area (generally ≥150mm x 70mm or as agreed upon by both parties).

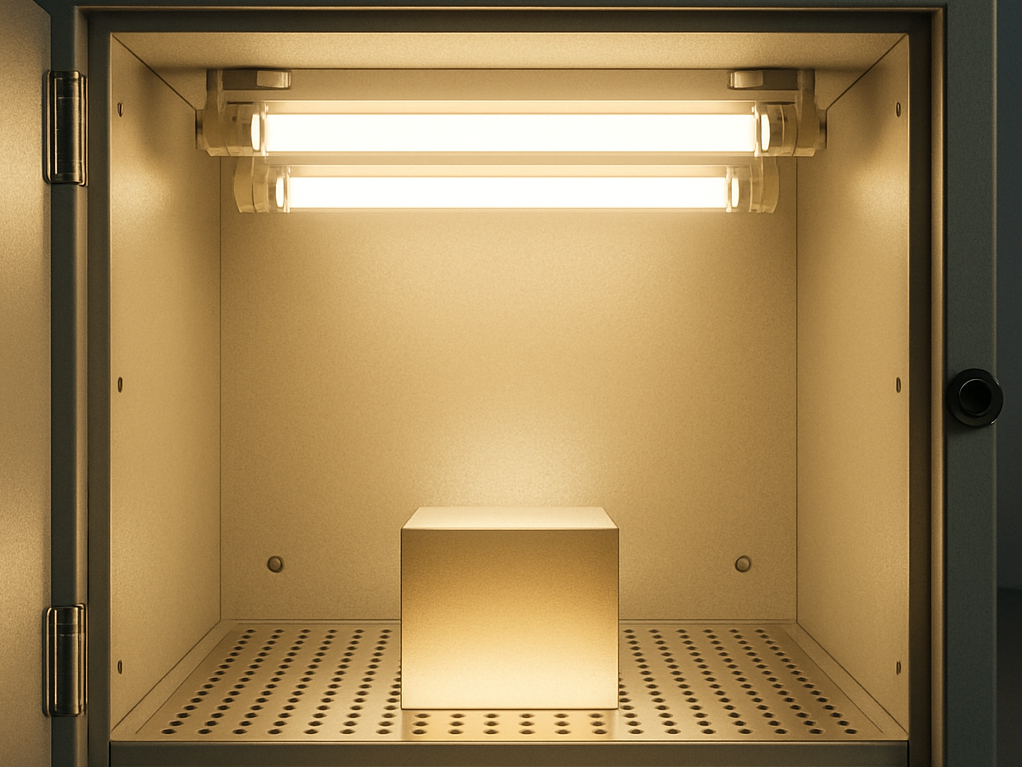

- Place the sample in the testing machine and set the exposure time and intensity.

- Color Difference Assessment: Visually compare the sample to a standard grayscale chart (DIN EN ISO 20105-A02) to identify ΔE changes and grayscale differences.

- Instrumental Assessment: Alternatively, a colorimeter or glossmeter can be used to measure color and gloss changes.

Evaluation Points

- This test is only applicable to dyed layers that have undergone outdoor exposure testing and have a light stability of 6 or higher. It is not suitable for test pieces with a light stability of less than 6.

- This test is suitable for quality control and batch acceptance, but is not suitable for new product development verification or to completely replace outdoor testing.

Summarize

ISO 2135 is a long-standing, reliable, and repeatable method for accelerated aging under artificial light. It's primarily used for quality control during production and has recently gained increasing application in aluminum anodizing. This test serves as a further stability verification for already tested outdoor products. This method offers a more efficient alternative to long-term UV testing of deteriorating items.