[Professional] Traditional sand casting

Sand casting is a mature and widely used metal forming process. It involves melting the desired metal (such as iron, aluminum, and copper) into a liquid state using molds, sand, templates, and models, then pouring the molten metal into the mold and allowing it to cool to form the desired shape. Sand casting accounts for over 80% of all castings produced using various molds and remains a crucial process in metal processing.

Sand casting primarily uses silica sand, mixed with clay, water, and other additives to increase bonding and strength. Common materials include lower-cost clay sand, as well as resin sand, chrome sand, and zirconium sand used for precision casting. This explanation will focus on the process itself, without delving into the details of the sand and materials used.

Sand casting process

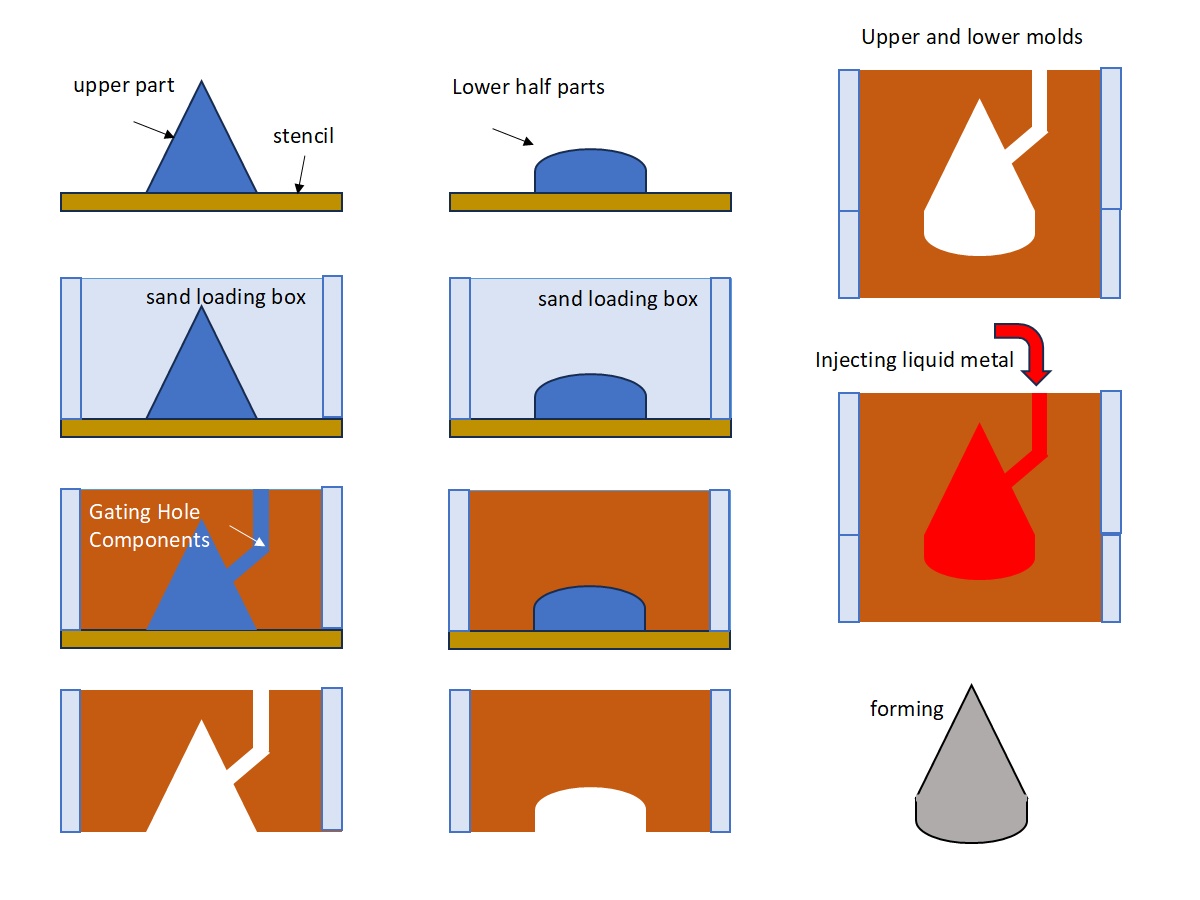

Here's a brief explanation of the sand casting process:

- First, place the upper half of the finished product model onto the mold.

- Place the metal upper sand box onto the mold, securing it to prevent movement and ensure proper sand filling.

- Add sand to the upper sand box in small amounts multiple times, compacting the sand using a tamping tool. Insufficient compaction will affect the surface of the finished product after casting; therefore, this step is crucial. Additionally, the pouring channel needs to be constructed during tamping, so the pouring hole model must be connected to the part model and extend directly out of the sand box for subsequent pouring.

- After the upper sand box is compacted, remove the part model and pouring mold.

- Repeat the process, placing the lower half of the finished product model onto the mold.

- Place the lower sand box onto the mold.

- Use a tamping tool to ensure sand is thoroughly compacted throughout the sand box to minimize defects.

- After the lower sand mold is compacted, the part model can be removed.

- The upper and lower sand molds are then joined together. Generally, the sand molds are designed with interlocking points; once they are securely fitted, the casting process can begin.

- During casting, in addition to the original molten metal, alloying elements (such as magnesium, silicon, copper, or zinc to achieve metallic properties), flux, degassing agents, refining agents, and modifiers are added to control the metal composition, improve fluidity, remove gases and impurities, and ensure casting quality.

- Finally, the finished product is removed from the sand mold, and the joint between the pouring channel and the finished product is cut off using tools such as an electric saw. Subsequent surface treatment on a lathe yields the finished product.

Advantages and disadvantages of sand casting

Advantages:

- Low cost.

- Short production cycle.

- Good shape freedom, capable of casting complex and large products.

- Suitable for diverse and small-batch production.

- No material requirements (metal).

Disadvantages:

- Low dimensional accuracy.

- Because it's a sand casting method, the surface of the part is relatively rough, requiring further surface treatment.

- Sand molds can only produce a finished product once and cannot be reused. Reproduction requires starting the process from scratch, resulting in high costs and making it unsuitable for mass production.

- Slow cooling rate; compared to metal mold casting, the mechanical properties are inferior.

Summarize

As previously mentioned, sand casting is one of the metal forming processes. While it offers advantages such as low cost and the ability to cast large objects, the surface finish of the casting can vary significantly depending on the size of the sand, pouring conditions, and additives. This process is less suitable for products with specific surface finish requirements.

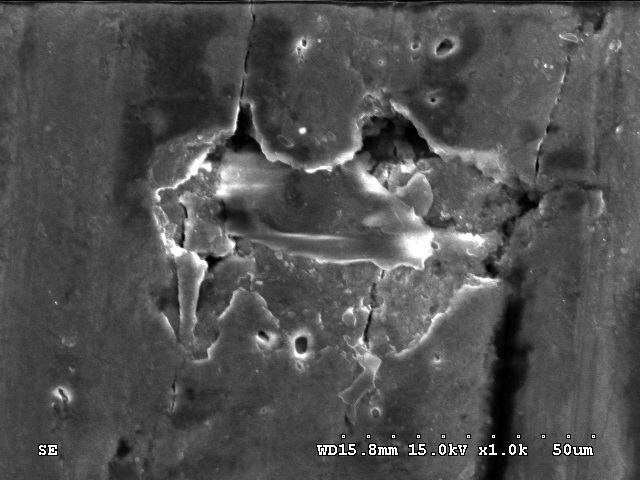

For example, sand holes (as shown in the right image), a common issue in sand casting, are a frequent occurrence in this process. This is mainly because excess sand was not removed from the sand mold after it was removed, causing the sand particles to combine with the metal after the molten metal cooled and solidified, resulting in sand holes.

Due to the numerous drawbacks of sand casting, die casting, metal mold casting, and lost-wax casting have been developed to improve the precision and surface finish of the finished product. We will introduce each process in detail later.