[Surface treatment] Familiar stainless steel

About stainless steel

Stainless steel is a metal we often hear about and see in our daily lives. Its most relevant applications are in insulated cups, tableware, and kitchenware, while it extends to building materials and equipment parts. This metal plays an indispensable role in our lives. In Taiwan, it has other names, such as stainless acid-resistant steel or water copper iron, and in Taiwanese, it's called "white iron."

Stainless steel is an alloy composed of different metal elements, combined with varying amounts of each metal to achieve the desired effect. A chromium content of at least 10.5% is required for stainless steel to achieve true rust resistance. Because stainless steel combines with various metal elements in different proportions, its composition is further defined by numerical values.

Rust-resistant stainless steel

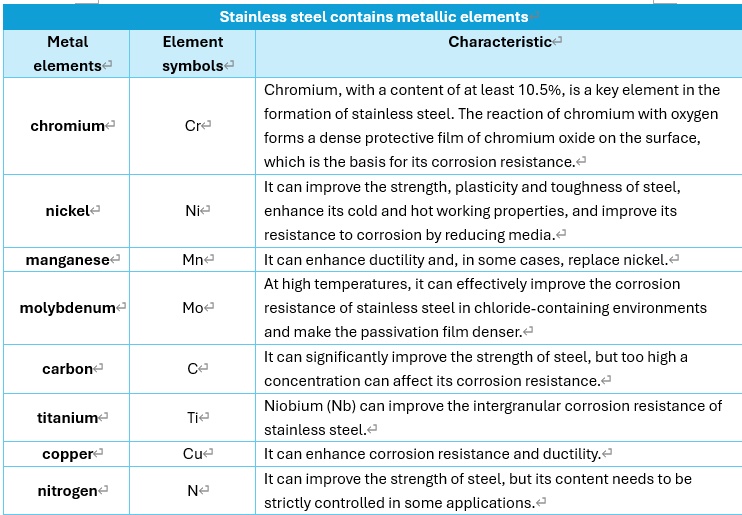

As mentioned earlier, stainless steel contains other metals to enhance its properties. Here, we will briefly introduce and explain them.

In the table, chromium and nickel are the most important elements in stainless steel. Chromium is mainly used to give stainless steel its corrosion resistance; a content of at least 10.5% is required for optimal corrosion resistance. Nickel, on the other hand, increases both the metal's strength and its corrosion resistance.

Internationally, stainless steel is defined by weight percentage. The minimum chromium content is 10.5 wt%, and the maximum carbon content is 1.2 wt%, classifying it as "alloy steel," or "ferroalloy" with a chromium content exceeding 10%. This designation indicates that it is not as prone to corrosion and rust as ordinary steel.

Common Stainless Steel Structure and Properties

There are five main types of stainless steel whose crystal structure changes with temperature and alloying elements: Austenitic stainless steel, ferritic stainless steel, montmorillonite stainless steel, duplex stainless steel, and precipitation-hardening stainless steel. We will briefly explain these here:

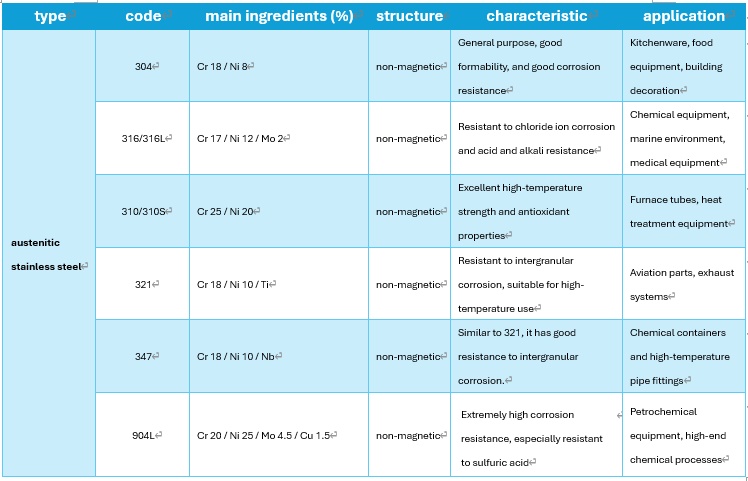

Austenitic stainless steel

Containing 16%–26% chromium and less than 35% nickel, it has the highest corrosion resistance, but cannot be strengthened by heat treatment and is non-magnetic.

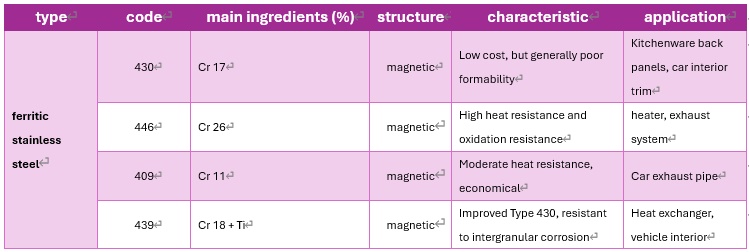

Ferritic stainless steel

It contains 10.5%–27% chromium but no nickel. Due to its low carbon content (below 0.2%), it cannot be strengthened by heat treatment and is only used in applications where corrosion resistance requirements are not high.

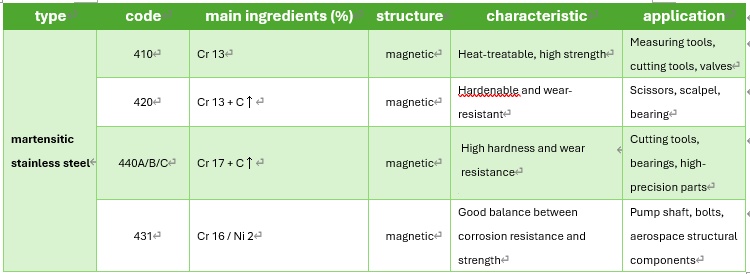

Martensitic stainless steel

It typically contains 11.5%–18% chromium and less than 1.2% carbon, and sometimes nickel. It can be strengthened by heat treatment and has moderate corrosion resistance.

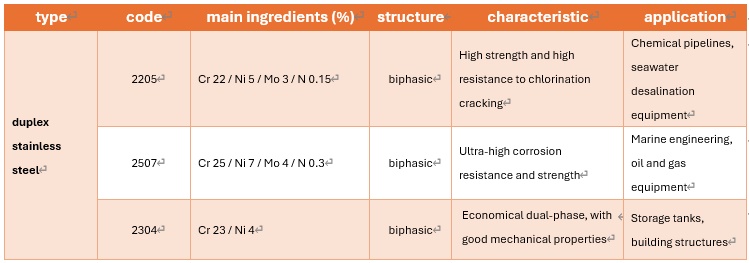

Duplex stainless steel

The microcrystalline structure is a mixture of Ostian and Feldspar stainless steel, with an ideal ratio of 50:50, while commercial products use a ratio of 40:60.

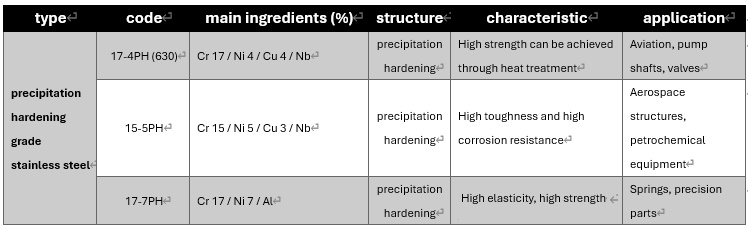

Precipitation hardening grade stainless steel

The matrix is a stainless steel with an osmotic or masmotic structure, which can be hardened (strengthened) through precipitation hardening (also known as age hardening).

Summarize

The article clearly shows that stainless steel is ubiquitous in our lives, providing us with convenience and safety. While there have been previous discussions about the effects of stainless steel on the human body, subsequent studies have verified that its release levels are extremely low and pose no threat.

However, it is recommended to replace utensils with abnormalities or scratches on their surfaces to maintain your health. Therefore, a better understanding of the metal materials we use allows us to make better use of them and improve our lives.